Quality Advantage

DC Motor ISO 9001 Manufacturer

King Right Motor has passed ISO 9001 certification since 2002 and was one of the few DC motor manufacturers that could pass ISO 9001 at that time and used this system to establish the company's complete management system process planning and preparation for international certification. Through this rigorous quality management system, we can completely construct the organizational background and plan the operation of the leading brand, strengthen the communication ability and operational support within the enterprise, establish faster risk thinking and more complete material preparation management, and make the company's operation more on track.

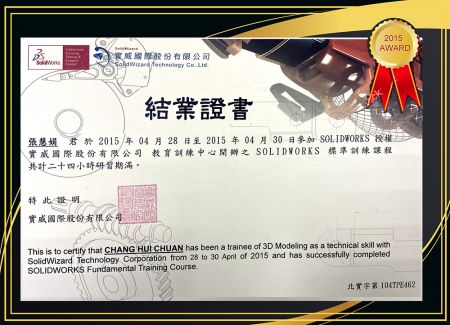

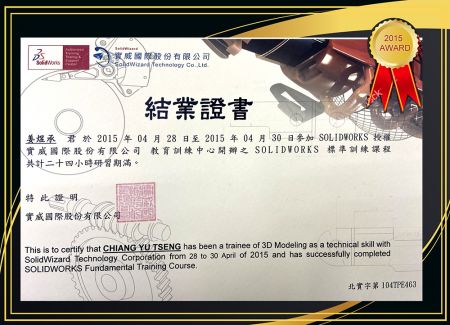

In 2015, in response to the trend of 3D drawing, the company dispatched two key employees to study Solidworks and obtain certificates. Unexpectedly, 3D drawing can not only check whether there is any interference between parts, but also 3D drawing files can be directly combined with the system of lathes and milling machines. It makes the processing not only accurate but also prevents and avoids interference factors such as overheating in advance.

In 2016, our company purchased two 3D printers, and the parts to be opened can be assembled by 3D printing first, so that the parts settings can be improved to the most perfect, so that the developed components have almost zero failures.

A motor is a mechanism that converts electrical energy into kinetic energy. Therefore, it is very important to provide input voltage V, current I and output torque T to assist customers in judging whether the motor is required by customers. In general measurement systems, information such as motor input voltage, current, output torque and rotational speed can be obtained from the measuring equipment, electrical parameters can be obtained by using a power analyzer, and mechanical parameters can be obtained by torque and tachometers. The remaining parameters, such as input, output power, and efficiency, are calculated mathematically.

King Right Motor has always provided the complete voltage, current and output torque curve table of the motor to customers for reference as the customer purchased the motor, so that customers can design the structure based on the curve table, and can better grasp the motor limit conditions, meet their requirements.